How To Get Glass Out Of Moto Z2 Camera Lens

Introduction

If your Moto Z2 Force camera is damaged or broken, this guide will show you how to supplant it.

For your safety, discharge your battery beneath 25% before disassembling your phone. This reduces the gamble of a dangerous thermal effect if the bombardment is accidentally damaged during the repair. If your battery is swollen, take advisable precautions.

Alert: The screen assembly of this device is comprised of a rigid midframe and a flexible plastic display that tin divide apart during disassembly. Excessive heat on the brandish tin can likewise cause it to bubble up or warp, and this is very difficult to remedy. If you programme on reusing the screen associates, heed all warnings carefully and do not utilise whatsoever rut on the display.

-

-

When separating the sides of the screen assembly from the device's frame, you lot will need to release five metal clips securing it in place.

-

Three of these clips are located on the left side of the device, and two are located on the right side.

-

You volition need to piece of work around these clips with your opening pick in order to fully release them.

-

You can either carefully slide an opening option around these clips, or leave a selection on one side of the prune while prying the other side with another pick.

-

-

-

Insert a Jimmy or other metal tool between the correct side of the plastic display and the metallic frame, near the telephone'southward side buttons.

-

Tilt the Jimmy downward while continuing to push it deeper into the gap to pry up the right side of the screen assembly.

-

-

-

With the Jimmy still inserted, insert an opening pick nether the silverish midframe, on elevation of the Jimmy in the same location

-

Remove the Jimmy.

-

-

-

Slide your opening option all forth the right side of the device to release the clips and adhesive securing the screen assembly.

-

-

-

Once the screen assembly'due south correct border is separated, slide your choice around the bottom right corner of the device then it is underneath the bottom edge of the associates.

-

Slide the tool all along the lesser edge of the phone to slice through the adhesive securing the screen associates and release the plastic clips.

-

Leave your tool underneath the bottom edge of the screen associates to preclude it from re-adhering to the frame. Continue to the next stride with a new tool.

-

-

-

When separating the left side of the screen associates, take care to non snag the display cable located on the left edge well-nigh the bottom of the display.

-

-

-

Insert another opening pick underneath the bottom edge of the screen assembly and slide information technology around the bottom left corner of the device so it is underneath the associates's left border.

-

Slide your tool all along the left edge of the telephone to separate the metal clips and adhesive securing the screen assembly.

-

-

-

Slide your tool around the pinnacle edge of the screen assembly and slice all along it to piece through its adhesive.

-

-

-

There are two large pads of agglutinative securing the screen assembly well-nigh the pinnacle border merely further past the 4 mm that have already been sliced through.

-

The front end facing sensor array and cable surround the correct patch of adhesive from the elevation and right, so prying or slicing from the top or right edge may damage the cable. The following steps will describe how to separate the adhesive from the left edge.

-

-

-

Apply a small corporeality of high concentration (>90%) isopropyl alcohol underneath the screen assembly's left edge, most the superlative of the device.

-

Allow the device to sit upright on its correct edge for ~5 minutes to allow the alcohol to penetrate and weaken the adhesive.

-

-

-

Insert an opening pick equally deep as possible under the top left corner of the screen assembly to slice through the left patch of adhesive.

-

-

-

Slowly and advisedly slide the flat stop of a spudger under the left edge of the screen assembly. Gradually insert it deeper to pry up the acme edge of the assembly and release the right patch of adhesive.

-

-

-

Lift the screen associates from the right edge and swing information technology open. It is all the same attached to the telephone chassis at the lower left border, then exercise not fully remove information technology yet.

-

If the screen assembly remains stuck, piece the adhesive repeatedly as needed.

-

-

-

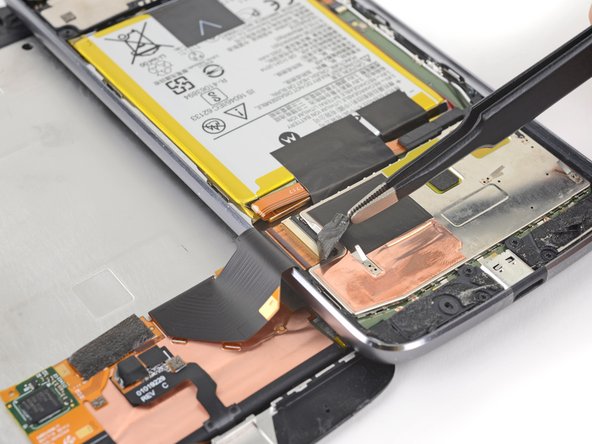

Use a pair of tweezers to remove the blackness piece of tape covering the battery connector.

-

-

-

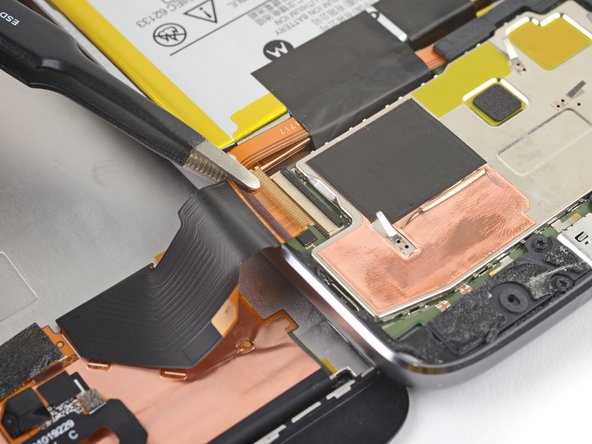

Employ a spudger to pry up the locking tab on the display cable's ZIF connector.

-

Utilize a pair of tweezers to slide the display ribbon cable out of the connector.

-

-

-

Remove the screen associates.

-

-

-

Utilize a pair of tweezers to remove the two black pieces of tape securing the battery.

-

-

-

Use an opening selection to pry upwards the small blackness bracket covering the battery connector. Information technology is secured with a minor bit of adhesive.

-

Use a pair of tweezers or your fingers to remove the subclass.

-

-

-

Use a spudger to pry up and disconnect the bombardment connector.

-

-

-

Unscrew the three one.7mm T4 screws from the speaker.

-

-

-

Apply the nylon spudger to lift and remove the speaker from the phone chassis.

-

-

-

Insert the flat end of the nylon spudger on the side of the rear facing camera closest to the bombardment.

-

Pry up the camera past pushing downwardly on the spudger until the camera pops upward.

-

-

-

Insert the apartment stop of the nylon spudger underneath the black lock.

-

Unlock the ribbon cable past pulling upward on the lock with the nylon spudger.

-

Separate the rear facing camera from the lath past pulling gently towards the bottom of the phone.

-

Conclusion

To reassemble your device, follow these instructions in reverse order.

Embed this guide

Choose a size and copy the lawmaking below to embed this guide as a small-scale widget on your site / forum.

Preview

Source: https://www.ifixit.com/Guide/Motorola+Moto+Z2+Force+Rear+Facing+Camera+Replacement/103317

Posted by: williamssignitere.blogspot.com

0 Response to "How To Get Glass Out Of Moto Z2 Camera Lens"

Post a Comment